FUSRAP Maywood Chemical Company Superfund Site Photo Gallery |

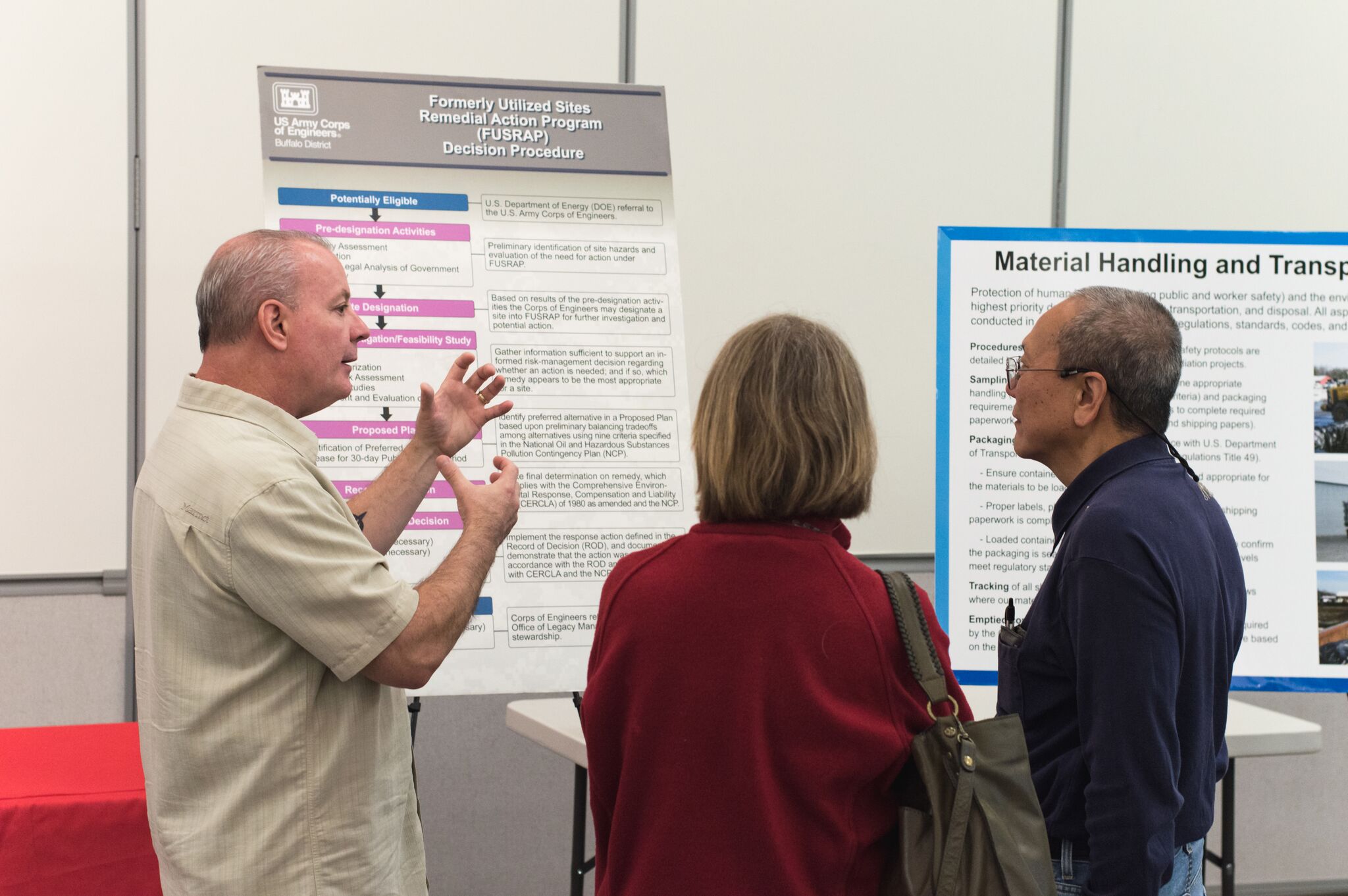

These photos represent the range of activities the Corps has undertaken since assuming

responsibility for the Maywood site (in November 1997) up to the present.

Return to Project Information

Community members and USACE representatives engaging at a recent public information session. |

|

Environmental science students from a nearby college tour the FUSRAP Maywood onsite lab. |

Visitors from a Korean university receive an onsite briefing. |

Student visitors from Korea and project representatives during a site visit. |

To learn more about Public Involvement, click here.

Back to the top of the page.

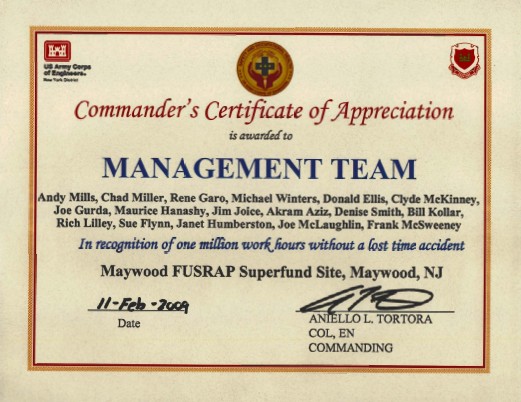

Together, the Army Corps and its remediation contractors have compiled an outstanding safety record at the Maywood Site. The project passed one million hours worked without a lost time accident (LTA) in December 2008, out of more than 1.4 million hours worked since project startup. This achievement was recognized with the New York District’s Commander’s Certificate of Appreciation awarded to the project in February 2009. As of February 2018, the project has compiled over 2.4 million hours without an LTA, which equals more than 5,400 consecutive safe work days.

USACE New York District Commander’s Certificate of Appreciation |

Various other safety awards earned by the FUSRAP Maywood Project |

Lt. Col. Kenneth McDonald, at the time Deputy Commander and Deputy District Engineer for the Corps’ New York District, congratulates a FUSRAP Maywood Site employee at a 2009 onsite safety award presentation. |

Back to the top of the page.

Groundwater investigations involve an in-depth field program to assess if and to what degree waste from the Maywood Site is affecting groundwater.

A groundwater monitoring well installation. |

Field crew collecting a groundwater sample. |

To learn more about groundwater investigations click here.

An air monitoring station at a remedial excavation site perimeter. |

Back to the top of the page.

Site characterization combines radiological, geotechnical, and environmental studies to accurately define the nature and extent of contamination on a property.

A worker sets the Geoprobe boring mechanism. |

The probe sleeve contains the soil sample. |

Engineering test pits provide information on an entire cross section of subsurface soil conditions. |

Excavated material from a test pit at a former retention pond. |

To learn more about Site Characterization click here.

Back to the top of the page.

The Corps completed remediation of the 22 remaining residential vicinity properties shortly after assuming responsibility for the FUSRAP Maywood Site.

The following four photos show a home in Lodi in various stages of remediation:

Prior to demolition |

Demolition underway |

During remediation |

New home construction (note: construction was completed by the homeowner) |

To learn more about Residential Cleanups, click here.

Back to the top of the page.

Scenes of remedial excavations at commercial site properties.

|

|

|

|

Remediation underway at Burial Pit 3 on the 100 West Hunter Avenue, Maywood vicinity property. Cleanup at all three historic waste burial pits at this property was completed in 2011. |

|

A radiation safety technician performing a surface walkover at a remedial excavation site. |

Technicians taking radiological measurements beneath the historic Lodi Brook culvert. |

Back to the top of the page.

Redstone Lane Park had contaminated soil below an underground drainage pipe and around the roots of several mature trees. The soil was safely removed in two stages: Stage 1 addressed the pipe and Stage 2 addressed the tree roots, with a scheduled break between the stages during the peak use summer months. The fully restored Redstone Lane Park was reopened to the community in August 2017.

Redstone Park prior to remediation. |

Soil removal around the drainage pipe and pipe replacement. |

Replacement trees and playground area |

Restored lawn and playground area |

Restored playground area |

Back to the top of the page.

As of February 2018, the FUSRAP Maywood Project has successfully managed nearly 127 million gallons of construction water. Water is either pumped directly from remedial excavations or into tank trucks for processing through an onsite water treatment system. The water is treated to comply with standards for radiological constituents under the project's permit with the local utilities authority, and then discharged into the public sanitary sewer system.

The modular settling tank at one of the onsite wastewater treatment units. |

Another view of the settling tank. Wastewater is initially stored in the blue tanks in the background as it arrives from the excavation sites. |

Back to the top of the page.

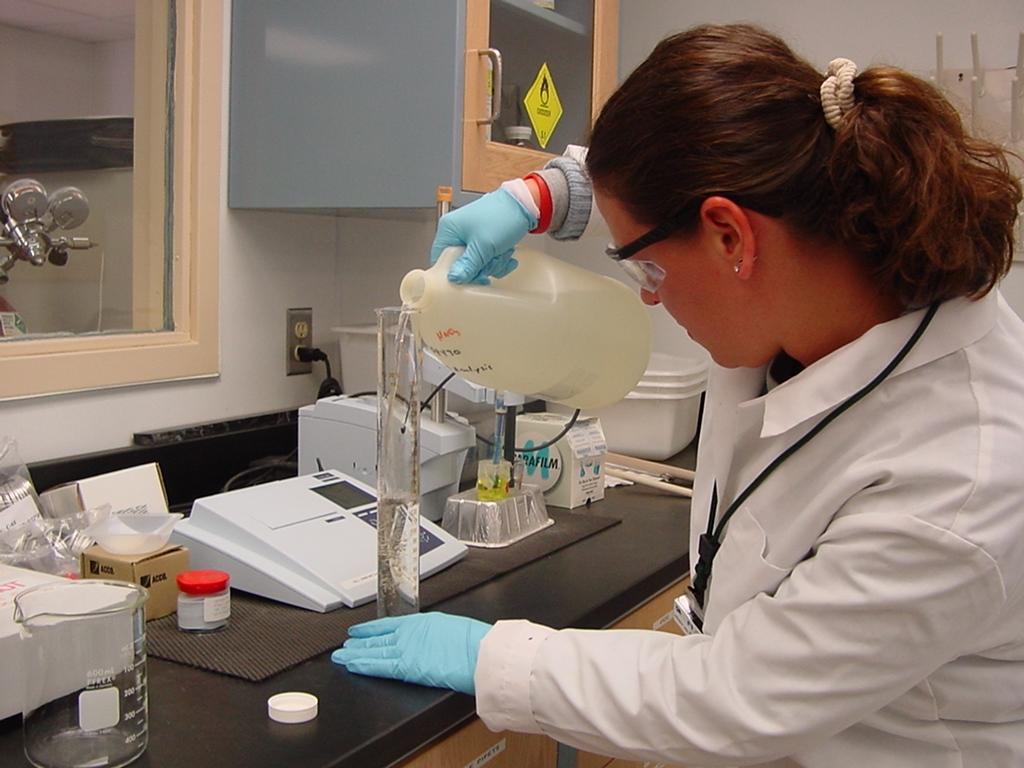

An onsite New Jersey DEP-certified and USACE-validated radiochemical laboratory is located at the MISS. The lab allows for more control of radioanalytical turnaround time by providing real time data, which in turn saves valuable remedial construction time and costs.

A lab technician loading air filter samples in Gas Proportional Instrument to measure gross alpha activity |

A technician transferring waste water to prepare for wet chemical analysis |

Lab hoods used to control hazardous vapors generated during wet chemical analysis |

Back to the top of the page.

Following remediation, properties are restored to their original conditions. The photos below show various stages of the restoration process.

|

|

|

|

|

|

|

Installing playground equipment following remediation of a local park. |

Back to the top of the page.

Back to the top of the page.

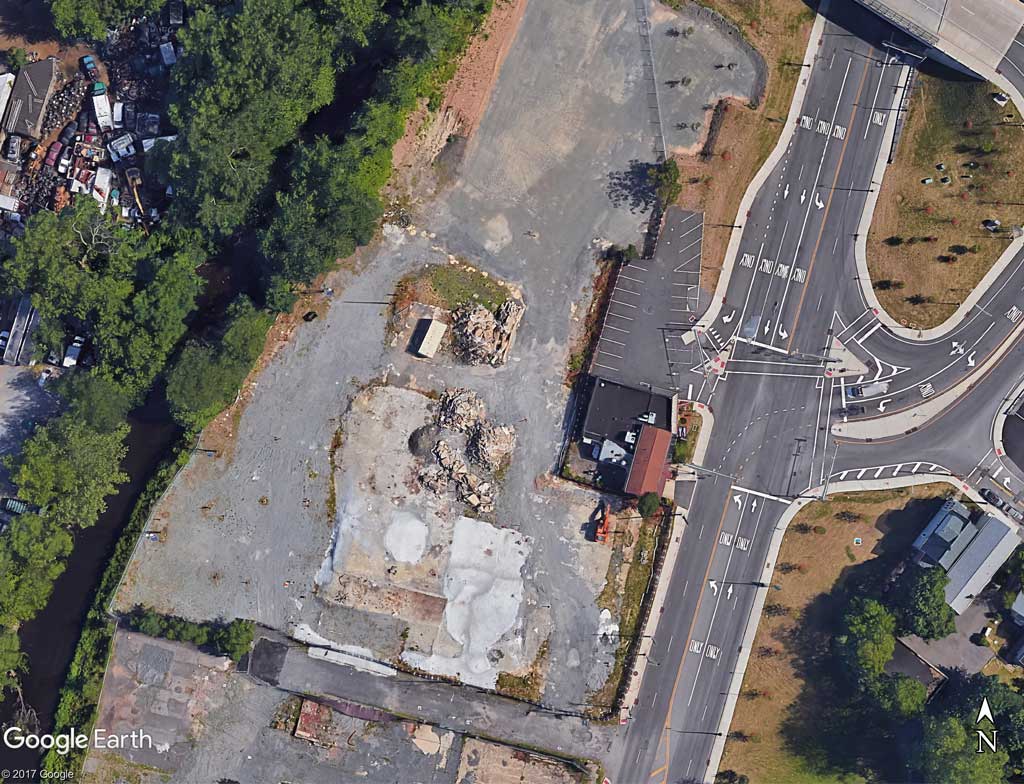

The next photo series shows various site properties before and after remediation. Property improvements or new development on these properties generate additional tax ratables for their communities.

|

Return to Project Information

Back to the top of the page.